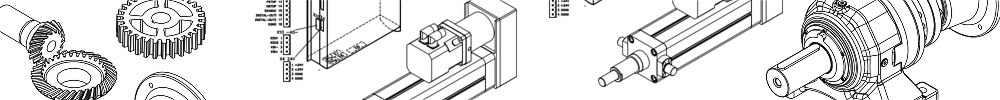

SERVO-DRIVE is proud to introduce its latest product line, Linear Rail Systems. The Linear Rail System uses a precision leadscrew assembly to provide controlled positioning along the axis of a robust linear slide. The Linear Rail System consists of a stationary base with a load bearing carriage that travels along a custom-extruded wear resistant aluminum rail. A Stepper Actuator powered Linear Rail System uses either a NEMA size 17 hybrid external linear actuator or for greater performance, an optional size 17 hybrid double stack external linear actuator integrated into the slide for a complete single axis positioning system, or the system may be is provided with various leads and shaft end configurations that accommodate virtually any source of rotary power.

SERVO-DRIVE is proud to introduce its latest product line, Linear Rail Systems. The Linear Rail System uses a precision leadscrew assembly to provide controlled positioning along the axis of a robust linear slide. The Linear Rail System consists of a stationary base with a load bearing carriage that travels along a custom-extruded wear resistant aluminum rail. A Stepper Actuator powered Linear Rail System uses either a NEMA size 17 hybrid external linear actuator or for greater performance, an optional size 17 hybrid double stack external linear actuator integrated into the slide for a complete single axis positioning system, or the system may be is provided with various leads and shaft end configurations that accommodate virtually any source of rotary power.

SERVO-DRIVE is proud to introduce its latest product line, Linear Rail Systems. The Linear Rail System uses a precision leadscrew assembly to provide controlled positioning along the axis of a robust linear slide. The Linear Rail System consists of a stationary base with a load bearing carriage that travels along a custom-extruded wear resistant aluminum rail. A Stepper Actuator powered Linear Rail System uses either a NEMA size 17 hybrid external linear actuator or for greater performance, an optional size 17 hybrid double stack external linear actuator integrated into the slide for a complete single axis positioning system, or the system may be is provided with various leads and shaft end configurations that accommodate virtually any source of rotary power.

SERVO-DRIVE is proud to introduce its latest product line, Linear Rail Systems. The Linear Rail System uses a precision leadscrew assembly to provide controlled positioning along the axis of a robust linear slide. The Linear Rail System consists of a stationary base with a load bearing carriage that travels along a custom-extruded wear resistant aluminum rail. A Stepper Actuator powered Linear Rail System uses either a NEMA size 17 hybrid external linear actuator or for greater performance, an optional size 17 hybrid double stack external linear actuator integrated into the slide for a complete single axis positioning system, or the system may be is provided with various leads and shaft end configurations that accommodate virtually any source of rotary power.

The Linear Rail Systems also offer control of slide bearing play with a patent pending self adjusting linear bearing. Integrated "T" slots accommodate full length support and various mounting options. Loads easily attach to the compact moving carriage with your choice of four or six screws. Designed to metric global engineering standards, the rail provides end to end axial stability and precise motion system accuracy. For extreme control, the Linear Rail Systems can be used with Servo-Drives's high precision anti-backlash nuts including "C" compression style, "W" wedge style, as well as Servo-Drive freewheeling "N" style nuts. Typical applications include medical, instrumentation, plant automation, CNC equipment, food and beverage automation, packaging and custom machinery.

Servo-Drive is recognized worldwide as a leader for stepper motor based linear actuators, rotary motors, lead screw assemblies, and sealed switches. The Company develops, designs and manufacturers internationally patented products for the global marketplace. The unique Servo-Drive designs provide precise, reliable motors with unmatched performance-to-size ratios.

In 2007 SERVO-DRIVE is introducing the GSM Series Actuators as the successor to the SR Series. The differences between the GSM and the SR Series of actuators is shown below. For the details associated with these differences see the links at the bottom of this page or go to GSM overview.

| Feature | GSM | SR |

| Connectors | In-line for all sizes | Side-by-side on SR31 and SR41 |

| Length | Shorter | The pin-to-pin mounting distance of the clevis mounts on the GSM is shorter than that on the SR |

| Width | The GSM30 is narrower than the SR31 | Side and trunnion mounting dimensions on the GSM30 are narrower than the SR31. The GSM20 and GSM40 side and trunnion mounting dimensions are the same as the SR21 and SR41 |

| Backlash | 0.2 mm | 0.1mm |

| Coatings | Anodized | Anodized end caps, epoxy coated motor case |

The EL Series linear actuators offer users all of the advantages of SERVO-DRIVEs patented inverted roller screw actuator designs in a Class I, div 1, Groups B, C or D* explosionproof package. These electromechanical systems provide process engineers a clean, fast, simple and cost effective replacement for hydraulic actuation and a longer life alternative to pneumatic actuation. The roller screw technology manufactured by SERVO-DRIVE outperforms rival ball screws by 15 times in travel life, and can carry higher loads. The compact design allows users to effectively replace hydraulic or air cylinders with an electromechanical actuator, yet meet all required capabilities of the application. The EL Series actuator is compatible with nearly any manufacturers' resolver-based amplifier. * "Class I" means that flammable gases or vapors may be present in the air in quantities sufficient to produce explosive or ignitable mixtures. "Division 1" means that hazardous concentrations in the air may exist continuously, intermittently, or periodically under normal operating conditions. "Group B" allows for atmospheres containing hydrogen, or gases (or vapors) of equivalent hazard, such as manufactured gas. "Group C" allows for atmospheres containing ethyl-ether vapors, ethylene or cyclo propane. "Group D" allows for atmospheres containing gasoline, hexane, naphtha, benzene, butane, alcohol, acetone, benzol, lacquer solvent vapors or natural gas. EL Series actuators are not rated for operation in atmospheres containing acetylene.

Haydon Double Stack hybrid linear actuators have improved force and performance. The various patent pending designs deliver exceptional performance and new linear motion design opportunities. Available in four frame sizes from 28mm to 57mm and three designs : captive, non-captive and external linear versions. The Double Stack series is available in a wide variety of resolutions, from 0.0031mm per step to 0.127mm per step. These motors can also be microstepped for even finer resolutions. Double Stack actuators will typically be used when the application requires more force than the single stack actuators can provide, especially with course pitch, high speed leadscrews.

SERVO-DRIVE gets focused on special variants and custom design of AC servomotors. Special design of shaft ( flat, helical cut, extended shaft, hollow shaft - example on the picture: special hollow shaft servomotor for pneumatic pick and place applications). Custom design flange for AC Servomotors brings compactiblity with brider spectrum of various drive systems. Special housing for requirement of a food industry (stainless steel housing), special painting, special finish, anodized housing or integration of servomotor into a customer's assembly. Special feedback devices like high resolution encoders both incremental and absolute, with various communcation buses like EnDat and Hiperface are available in every motor. Custom cable set, special connectors and feedback settings to match most servo amplifiers on todays market.

increased efficiency, reduced noise, longer life time. Servodrive has dramaticaly improve a CNC machining technology, that allow to efectively minimize seromotors cogging torque. Volume servomotors and torque motors are now produces in direct drive design. Hollow shaft, Low Inertia, Hight torque and excelent acceleration, allows this drives to be used in the direct drives turn tables to achieve more precize, stiffnes, robustness regulation fast position. Connected with high resolution feedback device ( precision in angle minutes ) compared to gearbox / ball screw solution, direct drives absolutely eliminates a hysteresis, back lash, elasticity and low accuracy of ball screw/gearbox drive system. mechanical effeciency is improved because of no loss on ball screw gearbox, either maintaning and operating cost are reasonable lower . Servodrive is able to eliminate the main direct drive disadvantage ( low speed ) by creating custom solutions for applications where high speed is required.

The asynchronous linear motors series LA use the same principle like rotative asynchronous motors to create a straight linear motion. In particular they are usable for conveyors, industrial manipulators, sliding gates, doors, boards etc. With this kind of construction it concerns three-phase asynchronous linear motors, that consist of two, a common magnetic circle forming, flat wrapped primary parts. Between the primary parts runs the secondary part made of aluminum or copper sheet with a thickness of 3 mm, which is usually a component of the impulse plant. In the basic version the engines need a direct supply of 3 x 400 V/50 Hz - frequency converter is not necessary. The engines need a linear situation giver, for the limitation of the distance a limit switch would be sufficient. - Due to the electromagnetic coupling between the primary and secondary part it is possible to drive the plant without mechanical connection elements (transmission, belt, wire, hoists...). The secondary part of the engine does not have to be supplied with energy. - The simple construction method and movement without contacts of the engine parts ensure a reliable drive without mechanical abrasion. - If the mechanical guidance should block itself or the drive gets "pressed" against the direction of motion, the drive will not be damaged. - The distance of the undercarriage is not limited. Special design - gentle starting - water cooling - encasing of the engine for the assembly in the external area - limit switch - electromechanical brake - safety light screen - remote control - customised solutions are possible according to consultation with the manufacturer